Ask a Question. Get a Quote.

Get answers for your process.

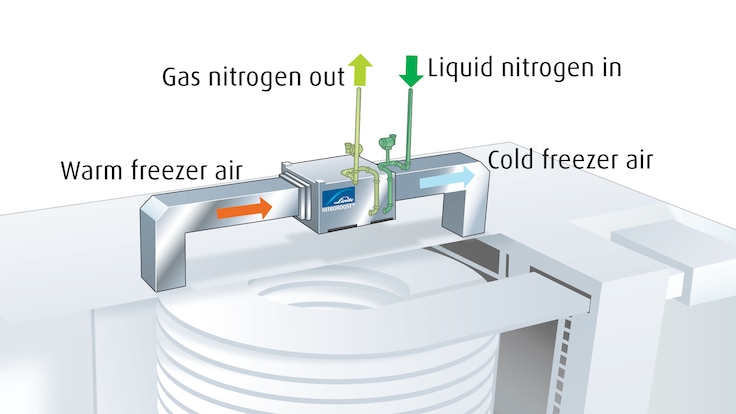

Contact usLinde developed the NITROBOOST ST & BL supplemental refrigeration systems to assist mechanical freezing units and meet production goals. The patent pending system installs on existing spiral and tunnel freezers or blast freezers and delivers a rapid, flexible increase to the refrigeration capacity. The NITROBOOST systems operate only when needed, making the technology a cost-effective option for optimizing capacity without having to invest in new equipment or a facility renovation. The systems use liquid nitrogen in closed-loop coils to efficiently and rapidly lower circulating air temperature. The NITROBOOST systems are compact in size and small enough to be mounted on existing mechanical freezers.

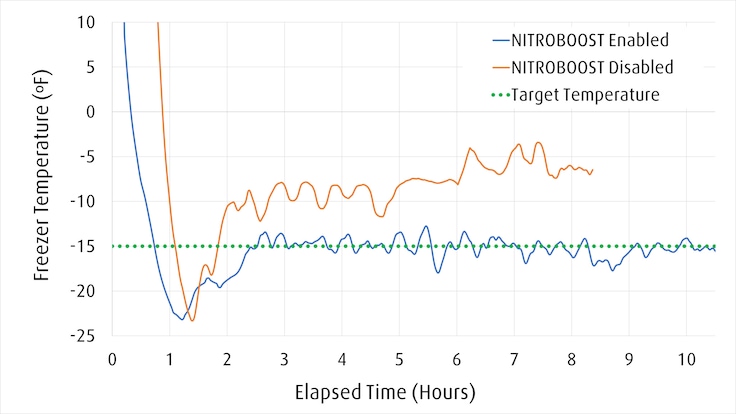

The add-on liquid nitrogen, closed loop system helps avoid production downtime and the related temperature issues that occur from high heat loads that exceed mechanical freezer capacity. The NITROBOOST ST system detects when the mechanical freezer is trying to reach its target operating temperature and triggers the liquid nitrogen flow to accelerate the cool down process to maintain a consistent operating temperature. The NITROBOOST ST system coils also can be set to defrost at different times relative to the mechanical system to optimize freezer production, defrosting and sanitation schedules. Download the boost information for straight tunnel and spiral freezers

Liquid nitrogen, a cryogenic fluid, is significantly colder than traditional industrial refrigerants, enabling rapid and efficient heat removal in a compact footprint. The liquid nitrogen heat exchanger coils are up to 75% smaller than ammonia-based evaporator coils. This compact design allows NITROBOOST systems to easily integrate on top of existing mechanical spiral freezers minimizing space requirements while maximizing performance.

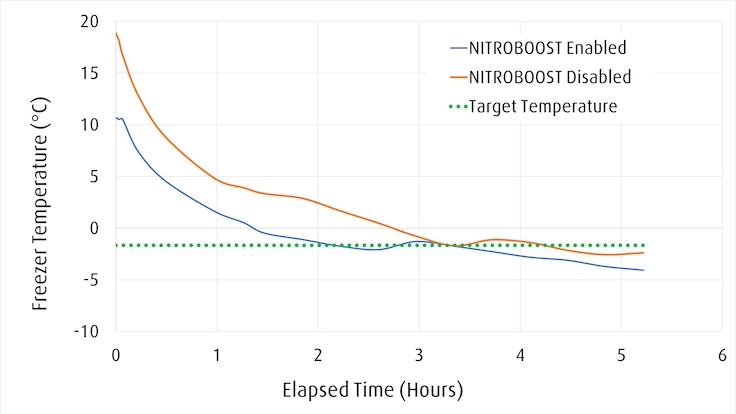

Mechanical blast or shock freezers can struggle to reach their target operating temperature in an acceptable amount of time due to inadequate refrigeration capacity. It is often difficult for food processors to address temperature issues, since replacing the freezer or upgrading the mechanical refrigeration system can be very expensive and require weeks of downtime. Added to a blast or shock freezer, the NITROBOOST™ BL system from Linde helps under-performing or overloaded freezers reach the desired operating temperature faster. Processors can now keep products within specific temperature ranges and avoid the need to reduce freezer loading or operate additional hours or shifts. Read more about boosting blast and shock freezers

Food manufacturers often rely on ammonia or freon refrigeration systems, that struggle to keep up when production demands change or were are undersized. The blast or shock freezer may be unable to reach its target temperatures quickly and may struggle to maintain a consistent target temperature during its production cycles. The NITROBOOST BL system addresses that concern helping to quickly lower and then maintain the desired internal freezer temperature.

See what else Linde provides for the food industry. Return to the Home Page